200m3/D Textile wastewater reuse system

Customer Country:Colombia

In the textile manufacturing industry, the wastewater generated due to the complexity of its production process usually contains high levels of TSS, microfibers, TDS, BOD, COD, pigments, and alkaline substances, etc. Therefore, in the water treatment industry, textile wastewater has become one of the most challenging types of water to handle.

Typically, textile wastewater requires a wastewater treatment system to first reduce the levels of TSS, color, hardness, COD, and BOD, while also removing suspended solids and other impurities.

Then, the wastewater can be further treated using ultrafiltration and reverse osmosis membrane separation technologies to remove fine particles, organic matter, and salts from the water, making the treated water meet the standards for reuse. This significantly conserves water resources, reduces the water usage costs for enterprises, and also minimizes environmental pollution, providing strong support for the sustainable development of enterprises.

Design basis:

1. Production water application:textile waste water reuse

2. Raw water TDS: 1800ppm

3.Chlorides:450ppm

4. System total inlet capacity :13m3/H

5. UF System production capacity:12m3/H

6. RO system production capacity:7.5m3/H

7.Outlet water TDS≤100ppm

8.Voltage:220V/60HZ/3P

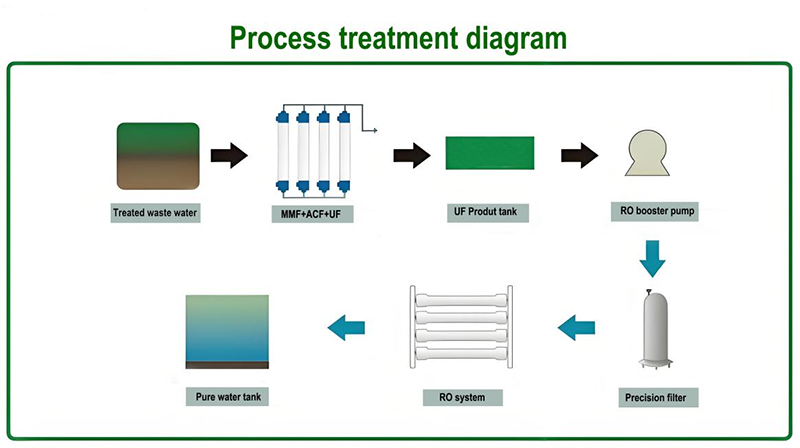

Process Flowchart: