480m3/DDouble-stage RO+EDI Ultra Pure Water System

Customer Country:China

Ultra-pure water plays a crucial role in the production process of new energy batteries, mainly being applied in the preparation of battery materials, the formulation of electrolytes, and the cleaning of batteries, to ensure the performance and safety of the batteries.

Ultra-pure water is applied in the battery industry, including the production of storage batteries, lithium batteries, solar cells, and battery plate grids,etc.

The water used in the electrolyte of batteries has very strict requirements. Generally, the conductivity of water should be less than 0.1 us/cm (resistivity over 10 megohms).

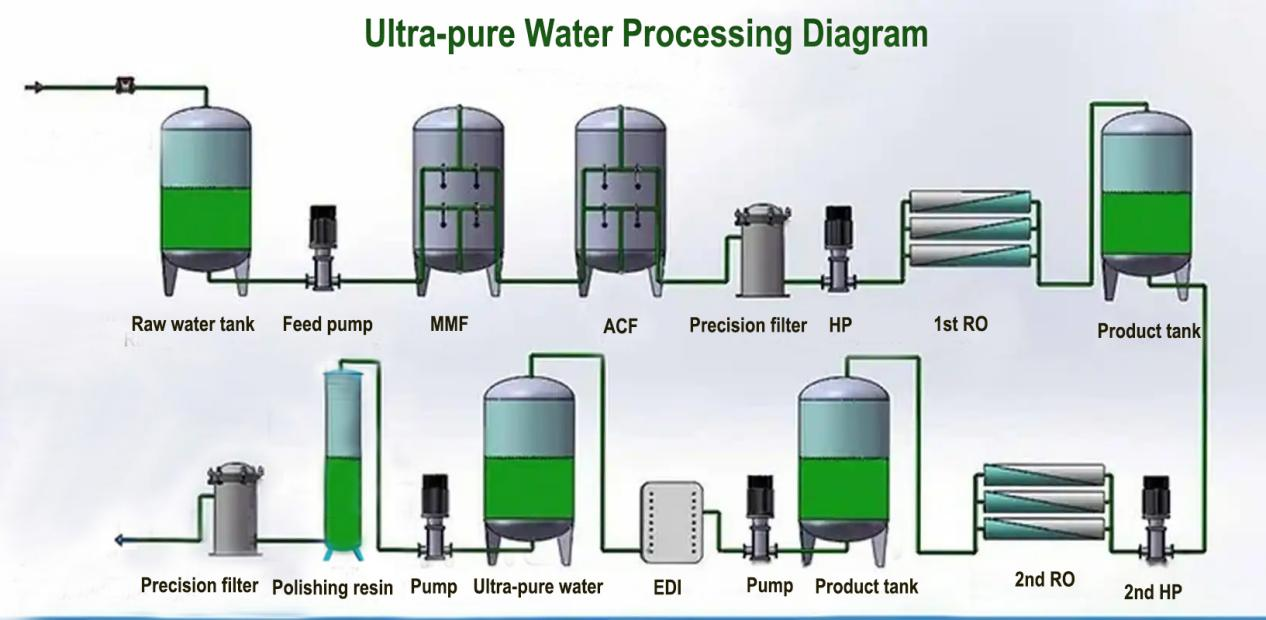

The traditional process for making ultra-pure water for batteries is the ion exchange equipment with both anion and cation resins. The disadvantage of this process is that the anion and cation resins need to be regenerated frequently. With the maturation of membrane separation technology, the current processes for making ultra-pure water are more often reverse osmosis + mixed bed ion exchange, OR reverse osmosis + electro-deionization (EDI).

The following is the main parameters of ultra-pure water for new energy batteries:

Design Basis:

1.Purified water application:

2.Raw water TDS: 250ppm

1. System inlet water capacity: 53m3/h

2. Primary RO outlet:35m3/h

3. Secondary RO outlet:24m3/H

5.EDI outlet capacity:24m3/h

6.EDI resistivity>15MΩ·cm

7.Recovery rate≥60%

8.Desalination rate: ≥99.8%

9.Voltage:380V 50HZ 3Phases

Process Flowchart: