News

What are the common contaminants of RO membrane? The nature and rate of contamination are related to the feed water conditions. Contamination develops gradually. If no early measures are taken, the performance of the membrane will be damaged within a relatively short period of time. Regularly testing the overall performance of the system is a good way to confirm the contamination of the membrane. Different contaminants will cause varying degrees of damage to the performance of the membrane .

(1) Suspended solids are commonly found in surface water and wastewater, with a size greater than 1 μm (colloids may be smaller than 1 μm). It can settle in a suspended state in undisturbed solutions (colloids remain suspended). After pretreatment, the indicators should be reduced to: turbidity < 1 NTU, SDI value < 5.

(2)Colloidal Pollutants are widely present in surface water or wastewater. They mainly exist at the front end of reverse osmosis systems and can be either single or compound substances composed of organic or inorganic components. Inorganic components may include silicic acid, iron, aluminum, sulfur, etc., while organic components may consist of tannic acid, lignin, humus, etc.

(3) Organic pollutants are generally adsorbed on the membrane surface. These natural humic organic substances originate from plant decay and are often charged.

(4) Biological contaminants are easy to form at the front end of the reverse osmosis system initially and then spread throughout the entire system. Common contaminants include bacteria, biofilms, algae, and fungi. The alert level for these contaminants is 10,000 cfu (colony-forming units) per milliliter. Therefore, it is essential to control biological activity.

The common fouling of reverse osmosis includes the following types:

(1) Membrane degradation:Reverse osmosis membrane can be degraded due to hydrolysis of the membrane (caused by too low or too high pH value for cellulose acetate membrane), oxidation (such as various oxidants Cl2, H2O2, KMnO4) and mechanical damage (water production back pressure, membrane roll protrusion, overheating, wear caused by fine carbon or sand materials).

(2) Sediment deposition: If no scale inhibition measures are taken or the measures taken are inappropriate, sediment deposition will occur. Common sediments include carbonate scale (Ca), sulfate scale (Ca, Ba, Sr), and silica scale (SiO2).

(3) Colloidal deposition is generally caused by metal oxides (Fe, Zn, Al, Cr) and various other colloids.

(4) Organic matter deposition: Natural organic matter (humus and griseocyanin), oil (pump seal leakage, new pipe replacement), excessive antiscalant or iron precipitation, and excessive cationic polymers (from pre-treatment filters) are all sources of organic matter.

(5).Biological contamination: Organisms will form biological slime on the surface of the composite membrane, and bacteria will erode the cellulose acetate membrane. These microorganisms include algae, fungi, etc.

What happens when the reverse osmosis system is contaminated?

The pressure drop between the feed water and the concentrated water increases.

The feed water pressure of the reverse osmosis changes.

The production water flow changes.

The salt permeability changes.

How to reduce faults and lower the frequency of reverse osmosis cleaning?

Design the reverse osmosis system based on a complete water quality analysis.

Determine the SDI value of the RO feed water before design.

Make corresponding design adjustments if the feed water quality changes.

Ensure adequate pretreatment.

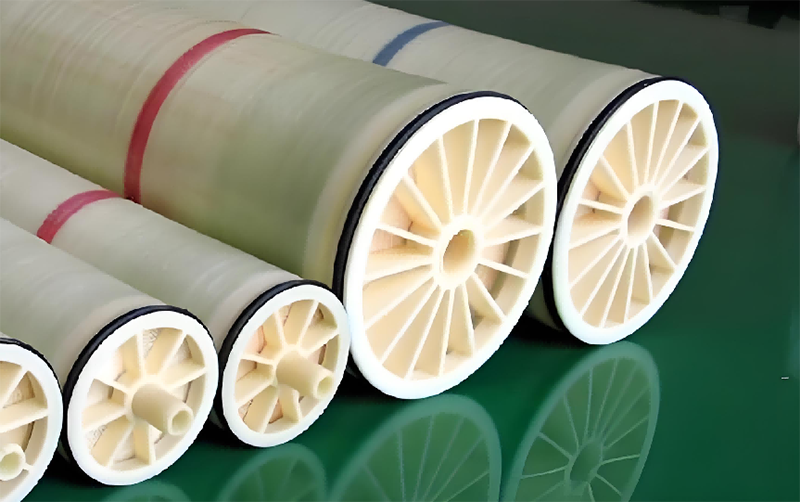

Select the correct membrane elements.

Choose a relatively conservative water flux.

Select a reasonable water recovery rate.

Design sufficient cross-flow and concentrate flow rates.

Standardize the operation data.