VOCEE Membrane is a manufacturer and exporter specializing in membrane separation technology, applied to water treatment systems and material clarification and concentration. Relying on profound industry experience and professional knowledge, we are dedicated to offering tailor-made solutions and all-round service support for customers, and providing customized equipment according to your specific requirements to ensure the stable operation and easy maintenance.

products sold in more than 100 countries

Years Industry experience

Customized system

Worldwide clients

In the textile manufacturing industry, the wastewater generated due to the complexity of its production process usually contains high levels of TSS, microfibers, TDS, BOD, COD, pigments, and alkaline substances, etc. Therefore, in the water treatment industry, textile wastewater has become one of the most challenging types of water to handle.

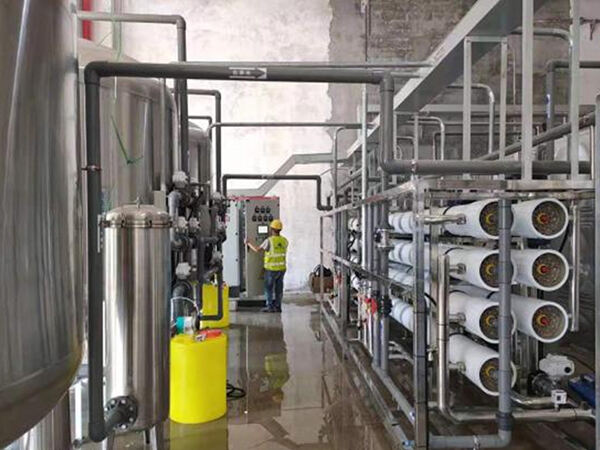

This user is dedicated to the production of frozen hydrobiological products for direct human consumption, such as cephalopods, crustaceans, bivalve molluscs, fish, echinoderms and fish egg cups, etc..Due to the insufficient local fresh water supply to meet the current production needs, sea water desalination equipment has been selected to provide sufficient fresh water for production.

Ultra-pure water plays a crucial role in the production process of new energy batteries, mainly being applied in the preparation of battery materials, the formulation of electrolytes, and the cleaning of batteries, to ensure the performance and safety of the batteries.

1.We will assign an engineer with over 10 years of rich experience in your required field to provide professional project coordination for you.

2. Provide the optimal solution free of charge in accordance with your requirements.

3.Provide process flow diagrams (PID), on-site layout diagrams and system structure diagrams (2D, 3D) based on the scheme.

1. Real-time updates of photos or videos of the equipment production progress

2. Support for reasonable changes to the equipment during the production process

3. Before the equipment leaves the factory, we can conduct tests on it using water of the same quality as in the actual to ensure that it meets the expected requirements.

1. Respond quickly within 12 hours and offer solutions within 24 hours.

2. We will send out the replacement parts within 72 hours if required.

3. If necessary, we can arrange engineers to repair the equipment at the buyer's site.

4. We provide long-term after-sales services, including free technical consultation, training services, and spare parts services.

Please Keep An Eye On The Developments Of Our Company